Viscosity of Beer

No Cleaning in Between Samples with microVISC PRO

For all beers, viscosity is a key marker of quality, directly linked to the "body" a consumer feels and the efficiency of the brewing process. For non-alcoholic beers, it is an essential measurement used to compensate for the loss of body that occurs when alcohol is removed, ensuring the final product isn't perceived as "thin."

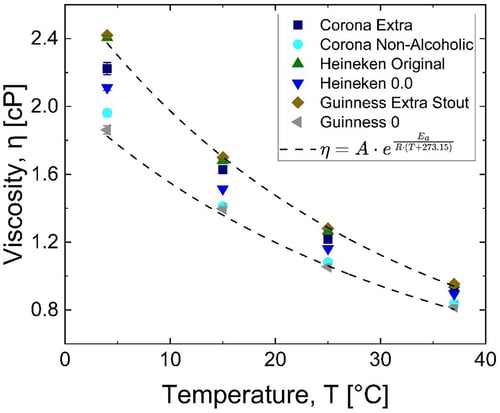

The plot below shows the viscosity vs. temperature (4 – 37 °C) of six commercially available alcoholic and non-alcoholic beers. All samples were measured with the RheoSense microVISC PRO equipped with the A05 chip and with shear rate of 8000 s-1. Each viscosity data point is an average of up to 11 repeats (data was filtered using the RheoSense Clariti data analysis software). The tiny error bars correspond to the standard deviation.

The viscosity of all the samples is ~1.9 – 2.4 cP for 4 °C, which drops to ~0.8 – 1 cP for 37 °C. The dashed lines are Arrhenius-like fits of the data for the highest (Guinness Extra Stout) and lowest (Guinness 0) viscosity beers. About 400 µL of degassed beer was aspirated to a disposable custom pipette; this process was repeated for all beer samples and temperatures without cleaning between samples. At the end of the sequence, PBS buffer with 1% Aquet was run as a cleaning solution. These results demonstrate the high repeatability of the continual sample testing provided by the microVISC PRO.

.png?width=200&height=58&name=RheoSense%20Logo%20(REGISTERED).png)

.png?width=300&name=Protein%20Viscosity%20initium%20one%20plus%20App%20Note%20Tile%20(small).png)

.png?width=300&name=Temp%20Dependent%20Viscosity%20of%20Cannibis%20initium%20one%20plus%20App%20Note%20Tile%20(small).png)