Run shear rate sweeps automatically

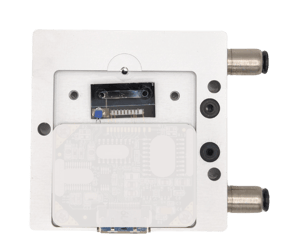

m-VROC II Viscometer — Controlled Shear Rates and Small Samples

m-VROC II is the next generation of leading semi-automated, small sample viscometer. Capable of the most demanding applications including small sample protein therapeutics, m-VROC II features the widest dynamic range viscosity measurement with as little as 10 microliters of sample. The m-VROC II allows you to get the most out of your samples with the ability to retest and reuse a single sample for multiple measurements.

This product can be configured based on your applications and there are multiple chip options you can choose from. Here is the chip selection guide!

.png?width=300&name=m-VROC%20II%20and%20CCS%20(NO%20BACKGROUND).png)

HOW IT WORKS

Understanding Fluid Behavior — Measuring Absolute Viscosity

With VROC® Technology, RheoSense took the standard principles of rheometry and created a dynamic micro-sample viscometer by adding microfluidics while reducing the size of the device with MEMS (micro-electrical mechanical systems) manufacturing. The result was a new platform which offers capabilities that are well beyond the limits of conventional viscometers in not only the sample volumes required, but the measurement range and precision.

- Shear Rate Sweep - 0.86 ~ 2,020,000 1/s

- Temperature Sweep

- Software Compatibility

- Barcode Reader Function

- Temperature Sensor Built-In

- 21 CFR Part 11

- Chips Specific to Your Application

- Minimum Sample Volume – 10 µL

- Characterization of Newtonian and Non-Newtonian Solutions

- Wide Viscosity Range: 0.4 ~ 100,000 mPa-s (or cP)

- Temperature specification of 4°C – 70°C*

- Accuracy up to 2% of Reading

- Repeatable Measurement up to 0.5% of Reading

- Compatible chips can be swapped out and automatically cleaned with the RheoSense Chip Cleaning Station

ONGOING SUPPORT

Our instruments are fully supported based on service plans. Select the best option for you below.

PLATINUM

Our all inclusive support package covers four chip repairs or calibrations, an onsite inspection of your instrument, three onsite visits, unlimited remote support, and unlimited mail in repairs for your instrument.

This package also includes 20 hours of dedicated protocol development to help your team get the most out of your instrument every year.

GOLD

Our mid-tier support package covers two chip repairs or calibrations, an onsite inspection of your instrument, two onsite and remote training sessions, and unlimited mail in repairs to your instrument.

This package also includes 20 hours of dedicated protocol development to help your team get the most out of your instrument every year.

.png?width=300&name=Mayo%20Viscosity%20m-VROC%20II%20App%20Note%20Tile%20(small).png)

-1.png?width=300&name=LNP%20m-VROC%20II%20App%20Note%20Tile%20(small)-1.png)