e-VROC

The only available extensional viscometer

Capable of measuring apparent extensional viscosity, e-VROC measures the extensional flow of polymer solutions to help you understand and optimize your industrial processes.

Evaluate your sample's reaction to extensional tension.

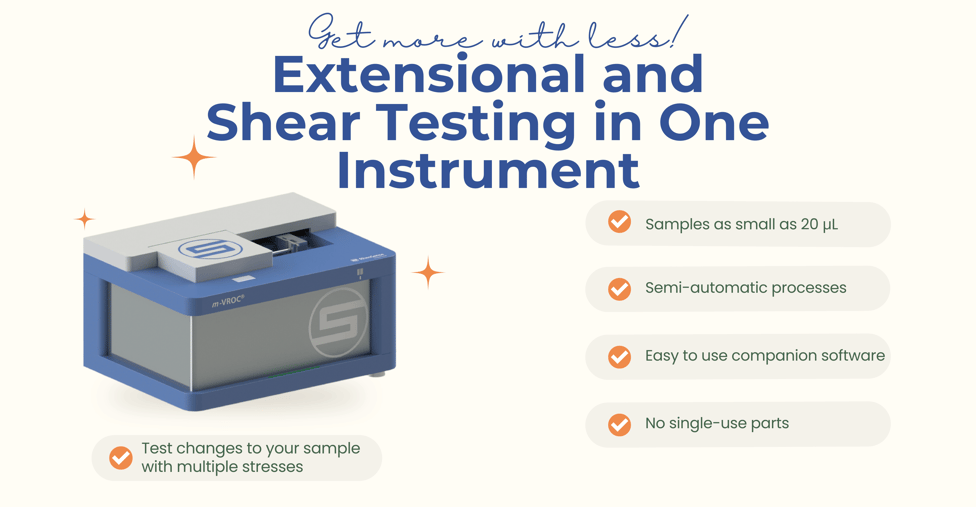

e-VROC® with m-VROC II

e-VROC®, the viscometer capable of measuring apparent extensional viscosity is back! Upgraded with the help of the m-VROC II, e-VROC now measures smaller samples, retests, and retrieves samples.

e-VROC measures the extensional flow of polymer solutions to help you understand and optimize your industrial processes. By monitoring the sample flow through a microfluidic contraction within the measuring cell, e-VROC® provides precise apparent extensional viscosity data.

Because extensional flows greatly impact the behavior of polymer molecules and asymmetric particles, understanding extensional viscosity allows you to improve your industrial processes. With accurate data, you can gain a deep understanding of the composition of the fluid, predict the impact of that composition on your process, and optimize your process based on the characteristics revealed by the data.

The viscometer measures the pressure upstream and downstream of a contraction using the MEMS pressure sensors, and it registers changes in the flow. The fluid undergoes an almost constant extension through the contraction/expansion, enabling the calculation of the apparent extensional viscosity.

-2.png?width=300&name=m-VROC%20II%20Image%20(No%20Background)-2.png)

e-VROC Chip Technology

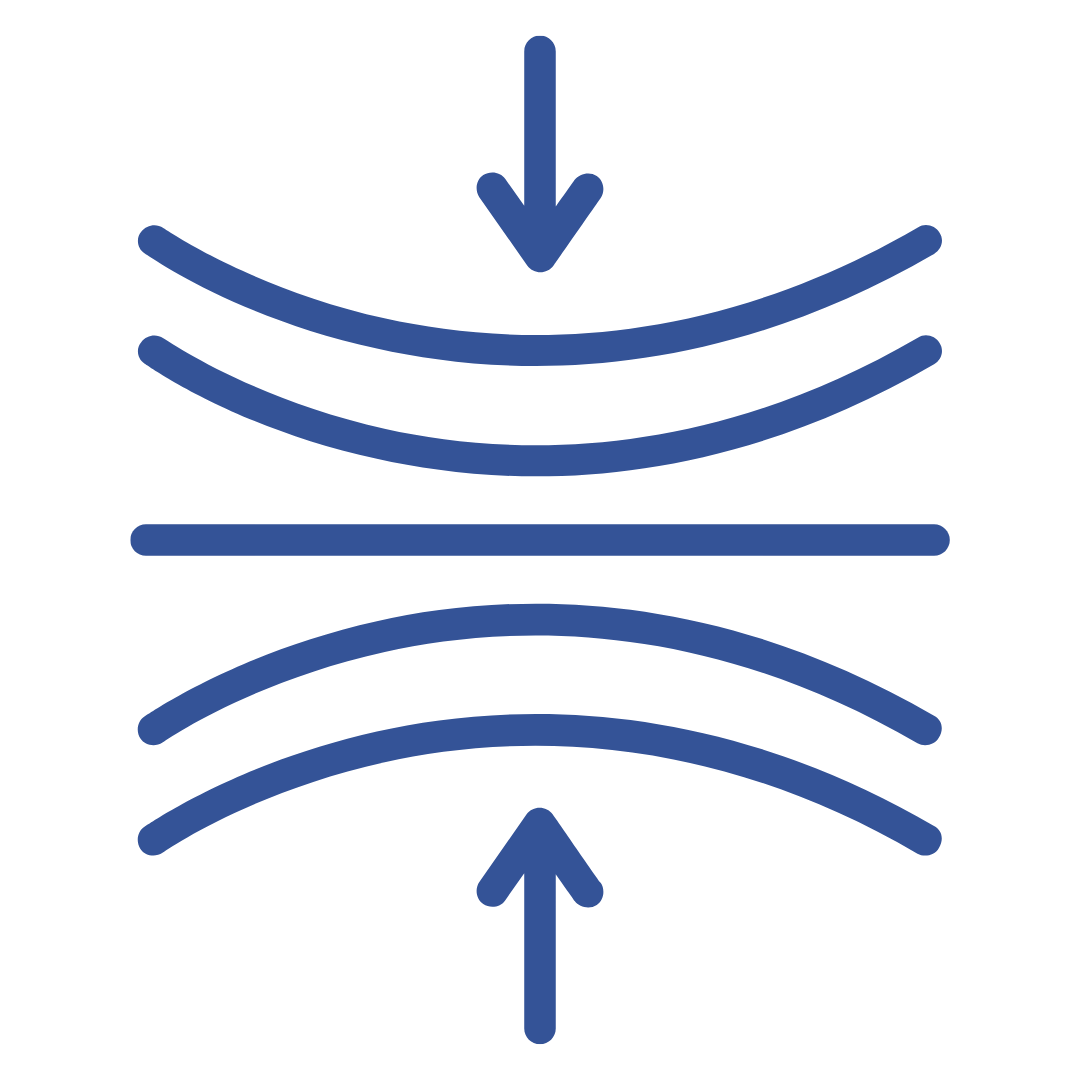

e-VROC® chip is engineered with a microfluidic channel of uniform width and depth. It has hyperbolic contraction/expansion zone in the middle of the channel and four monolithically integrated MEMS pressure sensors (two in the upstream and two in the downstream of the contraction/expansion zone). A liquid entering the channel first experiences shear flow in the straight channel and then experiences a uniform extension in the contraction zone as illustrated by the elongational shape change of the square in the schematic below.

Compared to other methods of extensional viscosity measurement, e-VROC® allows the measurement of extensional viscosity at high extensional rates.

- Extensional Viscosity

- Shear Sweeps

- Temperature Sweeps

- Accuracy ~+/- 2% Reading

- Repeatable Measurement up to 0.5% of Reading

- Typical Test Time <1 min

- Minimum Sample Volume – 20 µL

- Wide Dynamic Viscosity Range: 10 ~ 2,000 mPa-s

- Temperature specification of 4 °C – 70 °C

- Temperature Stability ~+/- 0.07 °C

- Extensional Rate: 0.1 ~ 5000 s-1

- No Evaporation – No Air-Liquid Interface

- Characterization of Newtonian and Non-Newtonian Solutions