Intrinsic Viscosity: Discover Molecular Weight

Molecular weight of polymers is measured by intrinsic viscosity

Polymers and biopolymers are essential materials in various applications such as biopharmaceuticals, oils, coatings, cosmetics, medical, and consumer products. Molecular weight of the polymers is critical property dictating physical properties, processibilities, and attributes of many products in these applications. Therefore, characterization of molecular weight is essential. Intrinsic viscosity is a routinely tested method to measure the molecular weight. The intrinsic viscosity, [η] is related to the molecular weight (M) by the well known empirical Mark-Houwink-Sakurada equation:

Constants, K and a are specific to a polymer, solvent, and temperature.

How to measure intrinsic viscosity

When a high molecular weight polymer is dissolved in a solvent, it forms a higher viscosity “blob” in the solution. As more and more polymers are added, the higher the viscosity of the solution becomes. Intrinsic viscosity is a measure of the viscosity increase that each added polymer molecule contributes. The higher the molecular weight, the more viscosity increases with each added molecule.

Thus, the intrinsic viscosity is defined by the equation:

|

Here, η is the viscosity of the solution, η0 is the solvent viscosity, and C is the polymer concentration.

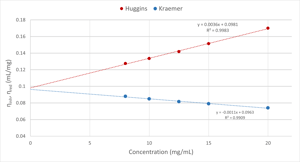

To measure the intrinsic viscosity, the viscosity of a solution is measured at different concentrations, for which the minimum and maximum concentrations have to be selected carefully. When a faster test is needed, viscosity measurement of a solution at a single concentration is often used as described in ASTM D4603-18.

Traditional Measurements & Drawbacks

Glass capillary viscometers, like Ubbelohde tubes, have traditionally been utilized in intrinsic viscosity measurements due to the high precision of these instruments. However, this style of viscometer requires extensive cleaning between samples and must be completely dry before continuing. This extensive cleaning and drying is tedious and time consuming, reducing the overall efficiency and throughput of testing. Glass capillary viscometers also require manual timing of each measurement, which can be erroneous and operator dependent.

microVISC PRO eliminates these drawbacks. Even a small sample volume can clear the full volume of the VROC chip, enabling continual measurements. The viscosity of multiple dilutions can be measured sample-after-sample without cleaning and all measurements are completely operator independent.

Learn more about measuring intrinsic viscosity in our application notes or on our blog!

Learn more in this easy-to-follow protocol for intrinsic viscosity analysis performed on a Bovine gamma globulin (BγG) solution prepared with Acetate buffer. This protocol steps through the derivation of intrinsic viscosity, and the process to calculate the intrinsic viscosity and Huggins coefficient using both conventional data software and RheoSense Clariti™ software.

Read Our Blog

Explore the comparison of Single-point and Multi-point Intrinsic viscosity methods for a number of polymers and bio-polymers.

Read our Application NoteSample Characterization - Simplified

Simplify your measurements with walk-up intrinsic viscosity measurements. microVISC PRO measures samples as small as 100 microliters in less than a minute, with no cleaning in between dilutions, making intrinsic viscosity a breeze.

View your data live during tests and easily export to RheoSense's Clariti software for data analysis.

Using intrinsic viscosity measurements, determine the size and interactions of your dilute.

Why microVISC PRO for Intrinsic Viscosity Measurements?

Intrinsic viscosity is critical in polymer research, development, production, and quality control. Traditional methods, such as manual glass capillary viscometers, are difficult to use, time-consuming, and prone to variations from operator to operator.

RheoSense microVISC PRO viscometer offers an advanced solution improving data quality and productivity even for highly volatile samples.

- Walk Up Ready – No training required

- High Throughput – More data in less time

- Fast, Precise Temperature Control

- Continual Measurements - No cleaning needed

- Cost-Effective – Performance without the premium price

/SoP%20-%20Intrinsic%20Viscosity.png?width=300&name=SoP%20-%20Intrinsic%20Viscosity.png)