The Critical Role of Viscosity in Electrospinning

Viscosity makes or breaks fiber

What is Electrospinning?

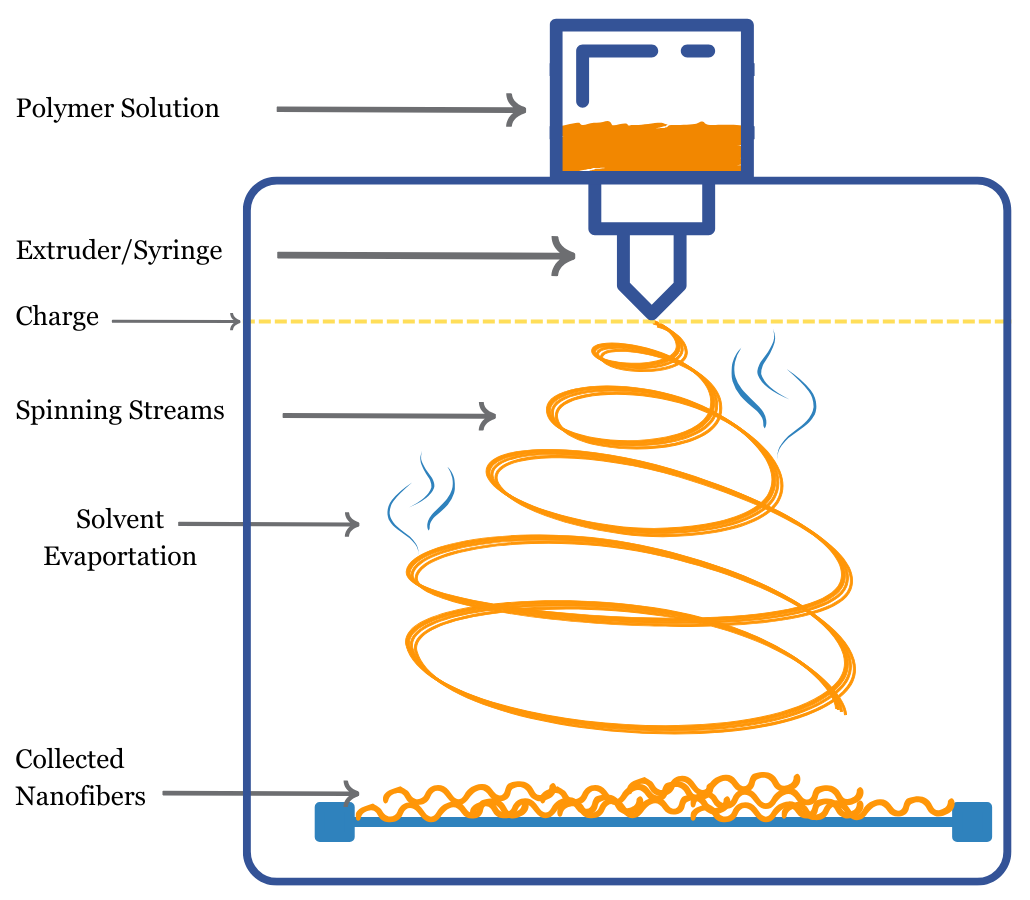

Electrospinning is the process in which functional fine fibers are produced from polymer solutions with assistance of high voltage. To form proper size of fibers, viscosity of the polymer solutions and choice of the solvent to ensure fast and proper evaporation and proper conductivity are critical. The viscosity of the solution must fall in right range. If the viscosity is too low, then fiber is not formed. If the viscosity is too high, electrospinning process will be inhibited. In electrospinning, the Berry number is a dimensionless index that indicates the degree of polymer chain overlap and entanglement needed for stable, uniform fiber formation. It is defined as:

C is the polymer concentration and [η] is the intrinsic viscosity. A Be value greater than 3 is generally considered suitable for stable fiber formation. Because concentration determines solution viscosity, measuring both the intrinsic viscosity and the actual solution viscosity is important for accurately assessing electrospinning processability. The selected solvent must be volatile so that fibers formed are solid, free of solvent. Tetrahydrofuran (THF) and hexafluoro isopropanol (HFIP) are examples of them. Because of the high volatility of the employed solvent, viscosity measurement of the solution and the intrinsic viscosity is difficult with conventional viscometers.

Limitations of Traditional Viscosity Testing in Electrospinning Applications

The requirement of a high volatile solvent in electrospinning solutions presents a unique challenge when measuring viscosity. The volatility causes a rapid increase in viscosity over time as the solvent evaporates. Conventional viscometers, such as rotational systems or glass Ubbelohde tubes, are open systems and cannot function without air-sample interface. This causes significant solvent evaporation as the solution is measured, resulting in poor accuracy.microVISC PRO produces highly accurate viscosity measurements of polymer solutions even with volatile solvents. It measures viscosity with closed, microfluidic channel VROC technology. The microVISC PRO also provides the necessary intrinsic viscosity measurements to develop an ideal electrospinning solution.In addition to ease of use, RheoSense viscometers are compatible with Clariti®️ software which provides quick and easy data analysis for electrospinning. Simply transfer your data to Clariti and apply the necessary calculations in the software.

What Parameters Impact Electrospinning?

TOUCH

Solution Viscosity

TOUCH

Solvent Volatility

TOUCH

Solution Conductivity

Solution Conductivity

Solution Conductivity

TOUCH

Concentration & Molecular Weight

Concentration & Molecular Weight

Concentration & Molecular Weight

Show more