Extensional Viscosity Technical Note

e-VROC Extensional Viscometer measures extensional (elongational) viscosity, providing extensional viscosity data by monitoring the sample flow through a microfluidic contraction within the measuring cell.

INTRODUCTION

Extensional deformation and extensional shearing have a significant impact on certain industrial processes, such as fiber spinning, paint rolling, roll coating, inkjet printing, spraying, electrospinning, enhanced oil recovery, drag reduction, and food processing. Regions of strong extensional flow can affect the final properties of the final product. Viscoelastic fluids often exhibit extensional thickening beyond the Trouton ratio. Because of this, it may be necessary to model and predict the behavior of these materials, accurately analyze their composition, and

predict optimal processing conditions for each characterized fluid. An extensional viscometer/rheometer-on-a-chip is the best technology to accomplish this.

PRINCIPLE

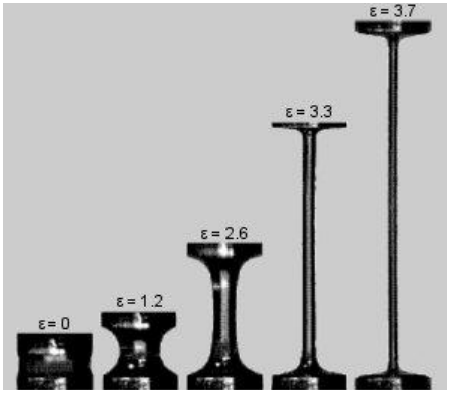

Extensional viscosity is a resistance of a liquid to stretching, whereas shear-rate-dependent viscosity is a resistance of a liquid to shearing. Imagine a liquid filament is stretched. As the extensional viscosity (ηE) increases, the force (σ) per unit area of the filament required to stretch at the same extensional rate (ε) also increases.

Figure 1: Extensional velocity increases, while the force required to stretch at the same extensional rate also increases.

Because extensional flows strongly orient polymer molecules and asymmetric particles, extensional viscosity has significant implications on the process and final product. In addition to the numerous industrial processes involving the extension of liquid filaments that were previously mentioned, other efforts also involve extension, including spreading butter, smoothing on lotion, and swallowing. Often, these processes are a mixed flow of shearing and extension, which means that both properties are important to understand for precise control. e-VROC™, an extensional viscometer powered by VROC technology, is an excellent tool for measuring extensional viscosity.

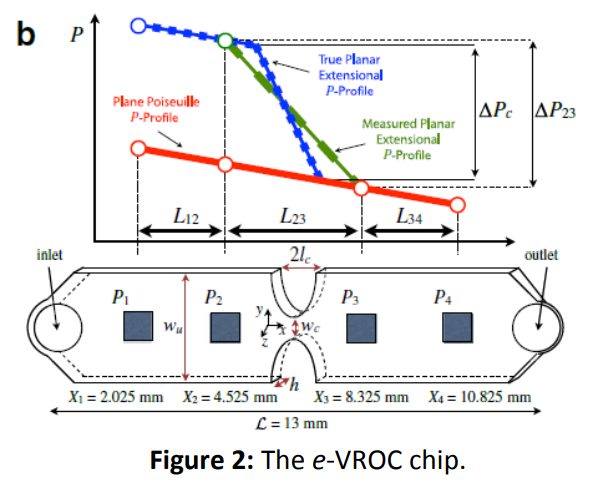

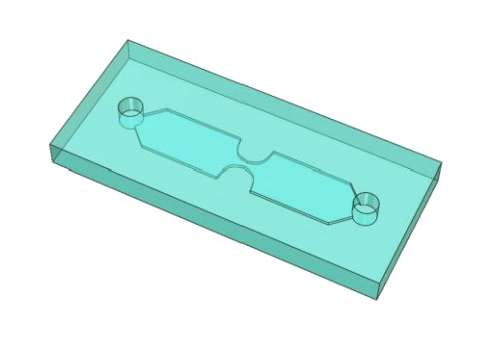

The e-VROC™ chip is engineered with a microfluid channel of uniform width and depth. It has hyperbolic contraction/expansion zone in the middle of the channel and four monolithically integrated MEMS pressure sensors (two in the upstream and two in the downstream of the contraction/expansion zone). A liquid entering the channel first experiences shear flow in the straight channel and then experiences a uniform extension in the contraction zone as illustrated by the elongational shape change of the square in the schematic below.

Figure 3: Hyperbolic contraction and expansion [Image taken from Microfluidic Extensional Rheometry Using a Hyperbolic Contraction Geometry]

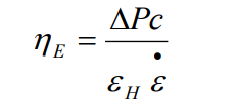

The extension causes an extra pressure drop as shown in the pressure vs. sensor position graph, ΔPc otherwise the pressure drop is solely attributed to shear. The apparent extensional viscosity is then simply calculated by the following equation1:

Where the Henky strain εH, and ε are given from the flow rate and the geometry of the contraction zone in the following:

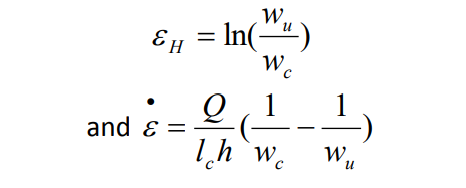

For a given geometry of the e-VROC™ fluidic channel, the extensional rate can vary based on the flow rate. Compared to other methods of extensional viscosity measurement, e-VROC™ allows the measurement of extensional viscosity at high extensional rates. The system measures the pressure upstream and downstream of a contraction using the MEMS pressure

sensors, and it registers changes in the flow. The fluid undergoes an almost constant extension through the contraction/expansion, enabling the calculation of the extensional viscosity.

Furthermore, as the two pressure sensors detect the pressure drop, the shear viscosity is measured simultaneously. This enables e-VROC™ to mimic the industrial processes where flow is generally a mixture of extension and shear. The advantage of the approach used with the e-VROC™ is that shear-rate-dependent viscosity and extensional viscosity can be provided at a specific temperature within the same measurement.

Note: Different ranges can be accessible depending on MEMS pressure sensor types. Customization of the contraction geometry is also available.

MEET OUR AMAZING TEAM

This is one of the eye catching layout variants of our team module. Portrait your team members with their name, job position, photo and optionally group them by department.

"I am not regularly running proteins of interest here to get viscosity data and the VROC performs extremely well (perhaps unsurprisingly).

.png?width=200&height=58&name=RheoSense%20Logo%20(REGISTERED).png)

-1.png?width=540&height=540&name=LNP%20m-VROC%20II%20App%20Note%20Tile%20(small)-1.png)